AUTOMATION in Welding is growing rapidly all over the world. Not only large companies but also medium and small businesses have understood that investing in this sector brings benefits in a short time in terms of productivity.

After all, all welding processes involving operations on pieces in series and in repetition can be automated. In addition to increasing precision especially on difficult processes, waste is reduced and welding is done faster and even over several shifts, decreasing the risks for the operator in terms of safety.

Once programmed, the robot will repeat the same weld with the same performance until the END command.

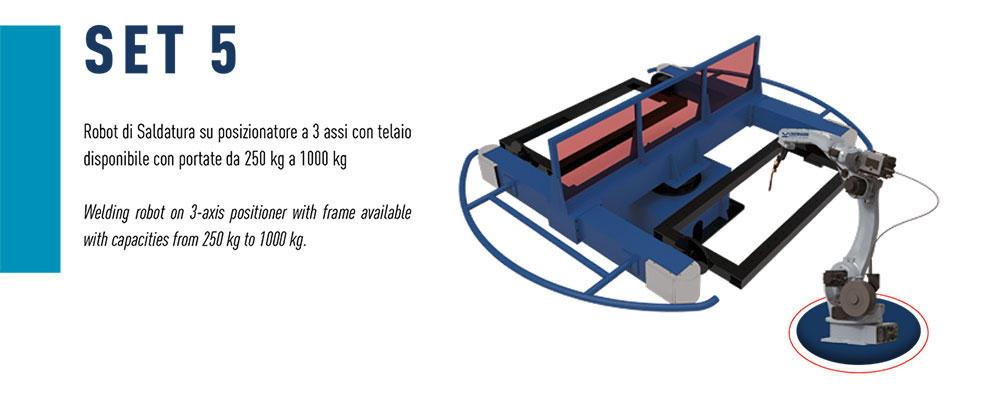

LOKERMANN offers its customers various solutions of industrial robots and positioners to be adapted to the needs of automated welding. All configured and built according to customer needs, in full compliance with all safety standards.

We offer a Consulting and Design service in an initial study phase of the system, then we take care of the installation and programming of the Robot and, finally, we take care of the training of the personnel who will have to manage and use the robotic system.

Our goal is to understand the customer’s needs and satisfy them with the right proposal by configuring the robotic cell so that productivity increases. Only in this way will the investment pay for itself in a short time.

We’ll take care of the assistance!

The LOKERMANN offer includes 3 sizes of Welding Robots with arm of different lengths 1454mm, 1730mm and 2012mm, all on 6 controllable and programmable axes from an easy-to-understand operating system.

The Robots are interfaced with our Grand Pulse 502 Robot welding generator and perfectly interpolated with all our positioners. The entire system is interconnected to software that monitors its activities and performance.